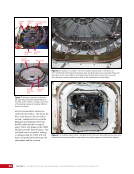

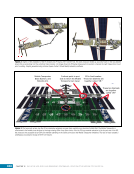

xxii Standardized racks are fundamental components of the ISS (Figure 6). These racks are carried up in US and Japanese cargo vehicles and transferred to the ISS where they fit into contoured rack bays. Some bays are outfitted with power, computer, cooling, vacuum, or ventilation systems. In this fashion, equipment can be taken to or returned from the ISS. Many of the core racks contain vital hardware such as computers and pumps, but research payloads are also supported in this fashion. Thus, for example, a rack to study combustion in space is installed into a bay. With a few quick connections for power, computer interface, cooling, and vacuum ducts, it is ready to conduct ground-breaking research either with the astronauts’ support or remotely from the ground. When its research is complete, the rack can be returned to Earth to be fitted with a new experiment. With the retirement of the Space Shuttle, several vehicles can transport racks to the ISS, but only one can return them to the Earth (Chapter 14). Figure 6. An example of a standard rack being installed in the Japanese Experiment Module. The rack is partially rotated into place on its pivot points (Chapter 3) while an astronaut works on connections behind it. To the right of the image is a fully installed rack. Another level of modularity on the ISS is that almost all hardware can be replaced. Wherever possible, systems consist of Orbital Replacement Units (ORUs). The ORU is designed so that if it fails—or, as happens in some cases, is upgraded—the astronauts can take out the old one and put in the new unit. This may sound obvious when designing anything, let alone a multibillion-dollar space vehicle however, it adds complexity and is a trade against cost and engineering challenges. For example, take a pump that moves cooling fluid around. The pump contains many elements such as electronics, motors, and valves, so there is always a chance that some component may fail. However, the

Purchased from Demo (abedemo.tizrapublisher.com) for the exclusive use of unknown. © 2026 Demo. Please report unauthorized use to pirate@tizra.com